Why does the sheet metal fiber laser cutter need automatic focusing?-Serena

Why does the sheet metal fiber laser cutter need automatic focusing?

Why we use automatic focusing

All we all know, one of the advantages of sheet metal fiber laser cutter is the high energy density of the beam. The focal spot diameter can be as small as possible to produce extremely tiny slits.

In the previous metal cutting applications. The focus of the laser head mainly relied on manual. However, with the continuous development of laser technology. The automatic focusing function eventually eliminated and replaced manual focusing. For example, a high-power laser cutting machine has an efficient automatic focusing function.

The advantage of automatic focusing

Some people think that the optical path of the sheet metal laser cutting machine is in the laser head. Can’t we simply change the height of the cutting head? For example, when the laser head rises. The focus position is high. And when going down, the focus position is low. However, it turns out that this is not as simple as everyone think.

First, there is a nozzle at the bottom of the laser head. During the cutting process. The distance between the nozzle and the workpiece (nozzle height) is about 0.5 ~ 1.5 mm. It can be regarded as a fixed value. Thus the nozzle height does not change. So it is impossible to adjust the focus by lifting the laser head.

Secondly, the focal length of the focus lens is constant. So it is unrealistic to adjust the focus by changing the focal length. If you change the position of the focus lens. You must change the focus position accordingly. If the focus lens goes down, the focus point will go down. If the focus lens goes up, the focus point will go up. This is a way of focusing. Using a motor to drive the focusing lens to achieve automatic focusing.

Another method is to place a variable curvature mirror (or tunable mirror) before the beam enters the focusing lens.

Changing the curvature of the mirror to change the divergence angle. And focus position of the reflected beam.

With the automatic focusing function. When processing workpieces of different materials and different thicknesses.

The machine can automatically adjust the focus to a suitable position automatically. This can significantly improve the processing efficiency.

And the perforation time of thick plates will also be greatly reduced.

Therefore, for high-speed sheet metal laser cutting machine, the automatic focusing function is an important and indispensable function.

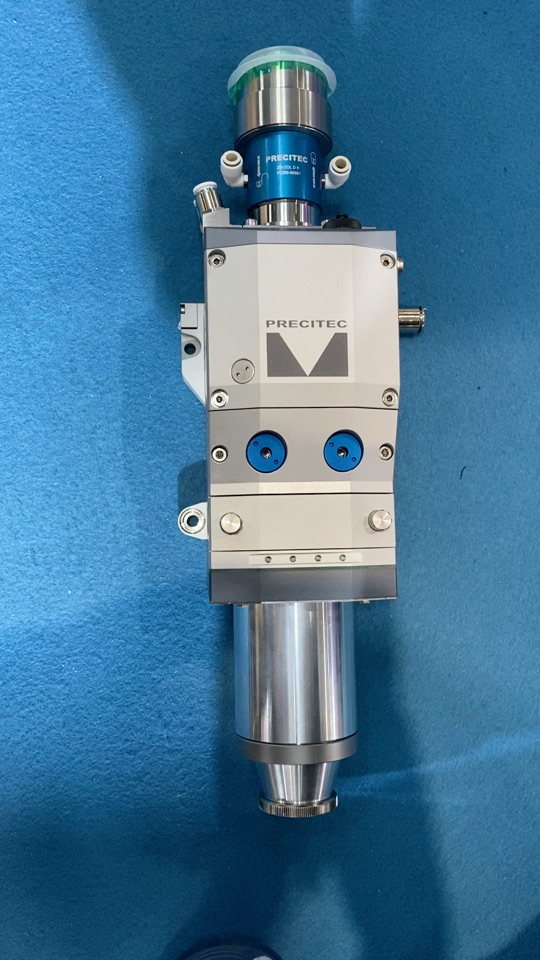

XT LASER has developed the auto-focusing laser head.The laser power is from 1000W to 2000W.

High precision and servo drive focus positioning accuracy less than 0.01mm. More details, welcome to contact us.