maintenance tips of fiber laser cutting machine in winter -lisa

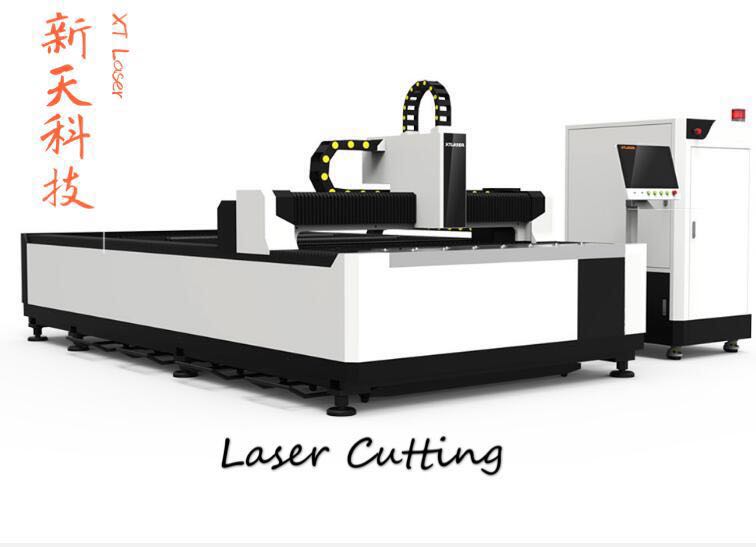

Fiber laser cutting machine

Maintenance tips of fiber laser cutting machines in winter

Winter is coming, and the temperature is plummeting.

In order to better extend the service life of the laser equipment, we must remind the new and old customers of doing the antifreeze measures for the equipment in winter. Because the price of laser equipment is expensive, as many as hundreds of thousands of millions.

Therefore, we should extend the life of the laser equipment to better save production costs and win greater benefits as long as possible.

This shows that the daily maintenance of the laser cutting machine is very important. Below, we will simply summarize some of the considerations

1 Water replacement and water tank cleaning of fiber laser cutting machine

We recommend to clean the water tank once a week and replace the circulating water once. Especially the laser tube must be filled with circulating water before working.

The water quality and temperature of the circulating water directly affect the service life of the laser tube. We we recommend to use pure water and control the water temperature below 35 °C. If it exceeds 35 °C, it is necessary to replace the circulating water, or add ice cubes to the water to lower the water temperature. (We recommend that the user choose a cooling machine or use two water tanks).

Another thing is cleaning tank. Firstly turn off the power, unplug the water inlet pipe, and let the water in the laser tube automatically flow into the water tank. Open the water tank, take out the water pump, and remove the dirt on the water pump. Then clean the water tank, replace the circulating water, return the water pump to the water tank. Insert the water pipe connected to the water pump into the water inlet. And arrange the joints. Power on the pump separately and run for 2-3 minutes (fill the laser tube with circulating water).

2 Fan cleaning of fiber laser cutting machine

The long-term use of the fan will cause a lot of solid dust to accumulate inside the fan, which will cause a lot of noise and is not conducive to exhaust and deodorization. When there is insufficient suction of the fan, turn off the power supply firstly, and remove the air inlet pipe and the air outlet pipe on the fan and the dust inside, then invert the fan and pull up the fan blades until it is clean. Finally install the fan.

3 lens cleaning of fiber laser cutting machine

We suggest to clean before work every day, so you should turn off the fiber laser cutting machine firstly

There are some mirrors and focusing mirrors on the laser machine. The laser is reflected by these lenses, focused and emitted from the laser head. Lenses are easily stained with dust or other contaminants, causing laser loss or lens damage. So clean the lens every day. Pay attention when cleaning:

We should wipte lens gently, and not damage the surface coating.

Also handle the wiping process gently to prevent falling;

Be sure to keep the concave surface facing down when installing the focusing mirror.

4 Rail cleaning of fiber laser cutting machine

Suggesting to clean the rail once every half month, and which must be in the shutdown state for this operation. As we all know that the guide rail and linear shaft are one of the core components of the equipment. And its function is to guide and support.

In order to ensure the machine with a high machining accuracy, the guide rail and the straight line requires to have high guiding precision and good motion stability.

During the operation of the laser equipment, a large amount of corrosive dust and smoke will be generate during the processing of the workpiece. Based on the long-term deposition of the smoke and dust on the surface of the guide rail and the linear shaft. The machining accuracy of the equipment will be greatly affected. And the etch point is formed on the surface of the linear axis of the guide rail to shorten the service life of the laser device. In order to make the machine work stably and ensure the quality of the products. It is necessary to carefully carry out the daily maintenance of the guide rails and linear axes.

Note: Please prepare the cleaning rails – dry cotton cloth, lubricating oil.