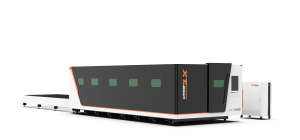

Advantage of hige power G type machine-Tulsa XT LASER

Advantage of hige power G type machine

1 Machine bed advantage

The working bedadvantage: machine bed are composited by truss beam,truss plate with septal support .

In order to match up with high-strength welding technology, high- temperature annealing to remove stress.

Deformation prevention, low vibration, and high cutting accuracy.https://youtu.be/2wa_b3vnJeE

2 Gantry

Advantage of Gantry:

Because of the rigid-flexible coupling analysis, the simulation performance is actual working conditions.

What’s more, from the beam and the motor torque acceleration, carries the multi-source load.

In conclusion, the reasonable layout design, high strength and strong stability, ensure long-term high speed cut.

3 Exchange table

High and low exchange working table, the exchange process is stable and fast.

The exchange table exchange time is just 15-22s.

4 software

Abundant human computer interaction interface, simple operation and easy to use.

To summarize, intelligent monitoring system design, real-time intelligent monitoring, safe production.

5 Servo motor advantage

The gantry type is double servo motor drive system and synchronous, double drive can effectively ensure the high speed.

So that high precision and high stability of the whole machine during cutting.

6 working table advantage

Such as segmented modular workbench, easy to disassemble and replace. Besides no hindrance to production, efficient and time-saving, safe production.

7 Cutting head advantage

Equipped with auto-focusing cutting head, can automatically. And accurately adjust the focus according to the thickness of the material. Suitable for a variety of focal lengths.

After all, shorten piercing time, improve piercing quality, high-speed cutting, and save time.

Thanks for your attention to XTLASER of laser machine. This is Tulsa, responsible for US and Canada market for more than 4 years. Served for more than 300 clients, profession in laser marking/cutting/welding/cleaning machine sales.

To sum up, if you have any questions about fiber laser marking/cutting/welding/cleaning machine, please feel free to contact us. We will very glad to help you and offer suggestions.

Contact Tulsa:

E-mail: xtkjwang@xtlaser.com Tel/whatsapp/wechat/skype: +86 13053849052

Give us a chance, we will not le you down.