Laser cutting in home appliance industry-Kalyn

Laser cutting in home appliance industry

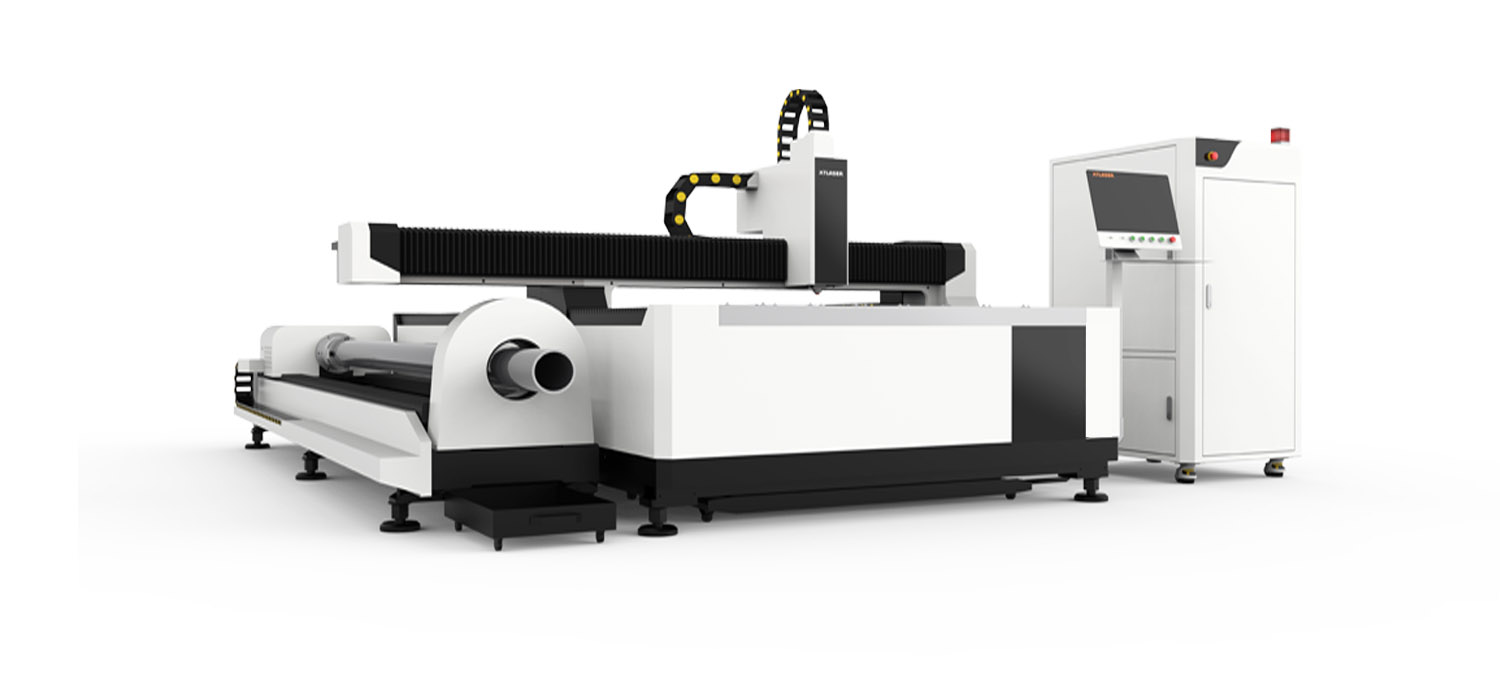

Laser cutting machine

Firstly,laser cutting machine could use in the electrical industry for the appearance of sheet metal parts,

and the installation of complete sets of electrical components for the cutting of steel parts.

Nowadays, after many electric appliance factories adopt this new technology,

they have improved the product quality, reduced the production cost, reduced the labor intensity, improved the traditional plate processing technology, and received better production benefits.

Electrical products, metal sheet processing parts accounted for almost all product parts more than 30%.

fistly,Traditional cutting and trimming technology is relatively backward, which directly affects product quality and production cost.

Laser cutting has the characteristics of higher cutting precision, lower roughness, higher material utilization and production efficiency,

especially in the field of fine cutting, has the advantages that traditional cutting cannot match.

Laser cutting is a non-contact, high speed, high precision cutting method that focuses energy into a small space and USES high density energy.

In the process of electrical equipment manufacturing, sheet metal parts and parts are many, the shape is complex, the process is difficult, in the process of processing need a lot of tooling and mold to ensure the processing quality.

so that Laser cutting technology can not only effectively solve the above problems in the electrical industry,

but also play an important role and value in improving the quality of workpiece processing,

at last saving processing links and processing costs, shortening product manufacturing cycle, reducing labor and processing costs, and greatly improving processing efficiency.

Recommended laser cutting machine