What result can you get with 50w fiber laser marking machine-Max

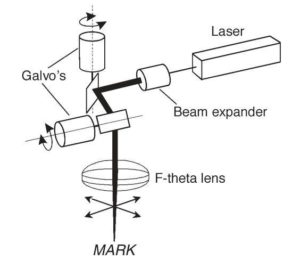

First let us see the working principle of fiber laser marking machine.

The laser marking is to use a laser beam to achieve permanent marks on a variety of material surfaces. The effect of marking is to expose the deep matter by removing the surface layer. Or to “mark” the trace through the chemical and physical reactions on the surface material based on the laser energy. Or to burn some positions of the material by laser energy to achieve the needed patterns and text.

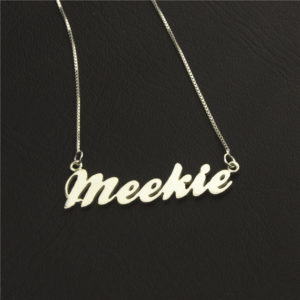

As mentioned in my blog “how to choose the right fiber laser machine among 20w,30w,50w and 100w”, 50w is used for engraving and cutting metal material, mainly for jewelry cutting.

1. Cutting samples and videos by 50w fiber laser marking machine.

2. 0.5mm Gold cutting result:

3. Silver cutting by fiber laser marking machine:

4. Features of fiber equipment

Firstly fiber laser marking machine can produce excellent fiber quality. Secondly This technology doesn’t require external chiller units , lamp changes. Thirdly Simple cleaning steps will ensure your laser running optimally for a very long time. Finally This makes the machine be better entry-level solution, which that many of our customers can learn easily.

5. How to clean the lens:

Firstly Optical lens might be polluted after a period of time in the working environment. If we do not do timely maintenance, the dust will corrode lens coating. The lens that coating damage can’t reflected light and through laser. oppositely it will absorb laser heat, affecting marking effect and easy to cause crack lens. Please use lens cotton to clean the lens. That is why you should use cotton to rotary clean from the center to the brink of the lens. Please do not wipe with coarse material wipe or touch lenses.

6. Lens should wipe gently and be sure not to damage the coating surface.

First of all, You can not wipe back and forth to clean the lens duing to lens is coated with a thin film because this film is very easy to break. Once the film is damaged, the damaged film will lead to a laser energy attenuation. So it will be a big problem. Besides the film, it should be clean and stay on the alcohol. And one cotton can be only used for one time.

7. Machine configuration

Fiber laser marking machine has integrated structure. It has no optical pollution, power of the coupling loss. And it is with compact structure.

8. Excellent beam quality

Excellent beam quality ensure that fiber laser marking machine can work on a variety of material with satisfying marking effects. So it is popular in customers.

9. Contact me:

Max Ruan

Email: xintian109@xtlaser.com