Lenses for your Laser Equipment-Bunny

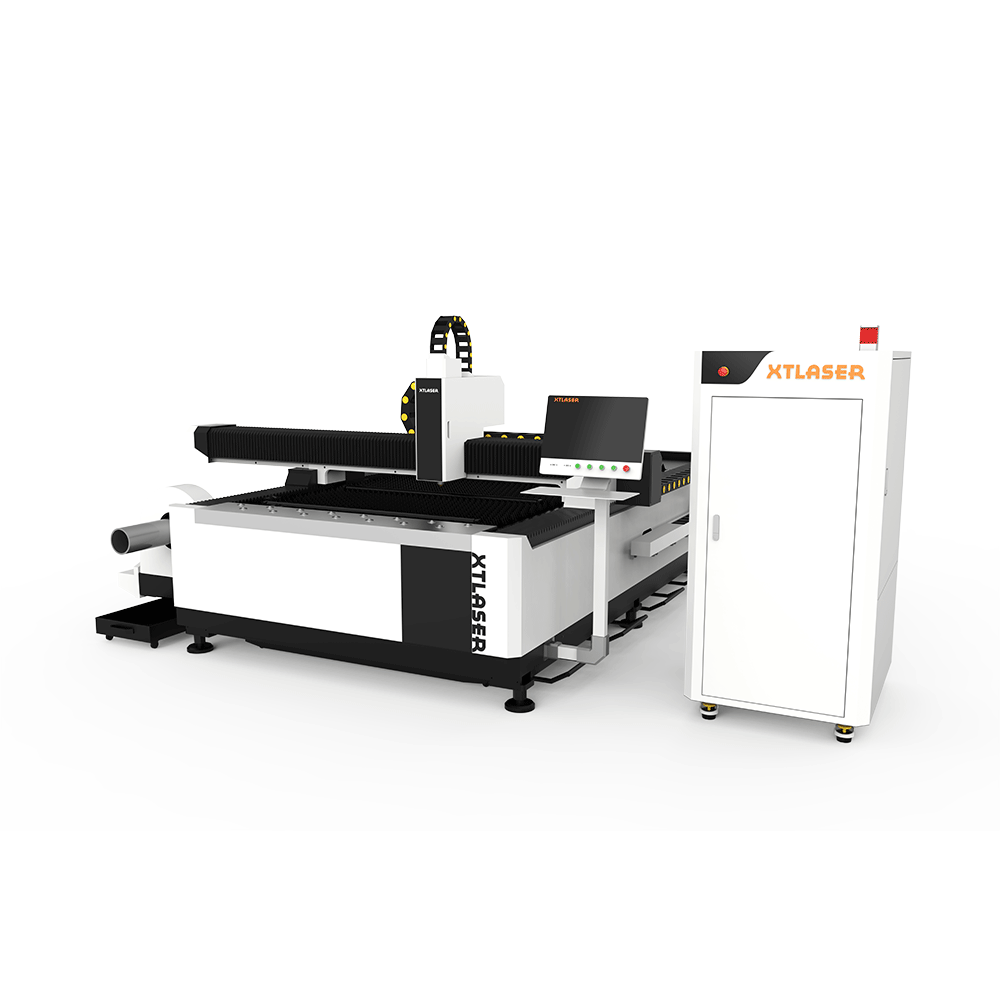

If you already have laser equipment, you are surely enjoying the benefits of reduced setup time, quality of cut and flexibility provided by this type of machine. In addition to this you can take advantage of your laser machine to improve the performance of components such as your lenses and mouthpieces.

If you want to improve the performance of your lenses you can choose the option of low absorption lenses.

These give you the following benefits with laser equipment:

-Absorption less than 0.10% (standard lenses have a maximum of 0.22%)

-2 to 2.5 times life increase from standard lenses

It is recommended to change your lenses when:

-It has surface imperfections such as:

- Scratches

- Hits

- Perforations

-It has contamination on the surface by:

- Metal burr

- Powder

- lubricant

- Footprints

Typically, laser lenses change every 1 to 3 months. Half of the companies change their own mirrors as factory training require to do this safely and optimally. Only% changes the resonator mirrors.

Friendly reminder: To develop a good habit, you need to turn on the gas to deflate before each cutting. During the debugging process, you need to check whether the gas selection is right or wrong. If the selection is wrong, no gas will cause the lens to break.

If you interest in receiving more information, you can contact us at xintian107@xtlaser.com