Analysis of technological parameters of laser deep engraving for several metal materials-Kalyn

Analysis of technological parameters of laser deep engraving for several metal materials

In the mold, signs, hardware accessories, advertising boards, car license plates and other products, the traditional corrosion process will not only bring environmental pollution and low efficiency. Compare with the traditional way of metal deep carving, laser metal deep carving has the advantages of no pollution, high precision, flexible carving content and satisfying complex carving technology.The common metal materials for deep carving are carbon steel, stainless steel, aluminum, copper and precious metals.

1. Effect of defocus on engraving depth

At firstly,the maximum depth corresponding to different defocuses.Base on the above data, it is conclude that a certain amount of defocus is need for deep carving on the metal surface to obtain the best carving effect.The defocus of engraved aluminum and brass is -3mm.Carvings of stainless steel and carbon steel have a defocus of -2mm.

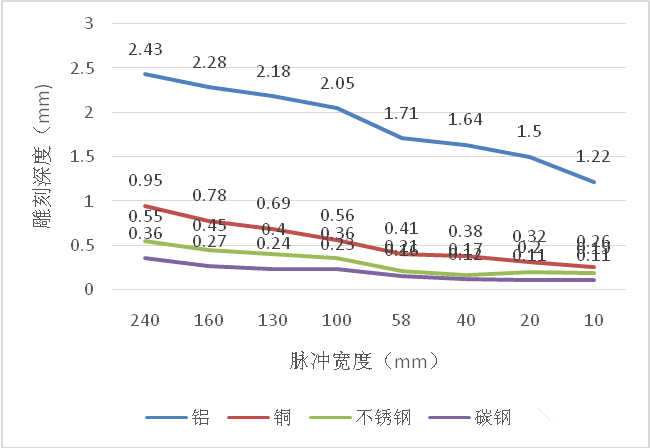

2.Effect of pulse width on carving depth

Secondly,it can see from the diagram that rfl-100m sculpte.As the pulse width decreases, the carving depth decreases.At 240ns, the carving depth of each material is the largest, which is mainly due to the reduction of pulse width leading to the reduction of monopulse energy.This reduces the damage to the metal surface.Resulting in less and less depth.

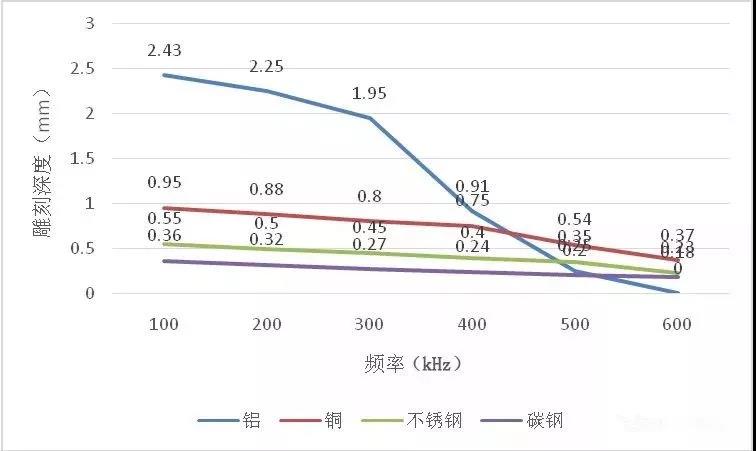

3.Frequency affects the depth of engraving

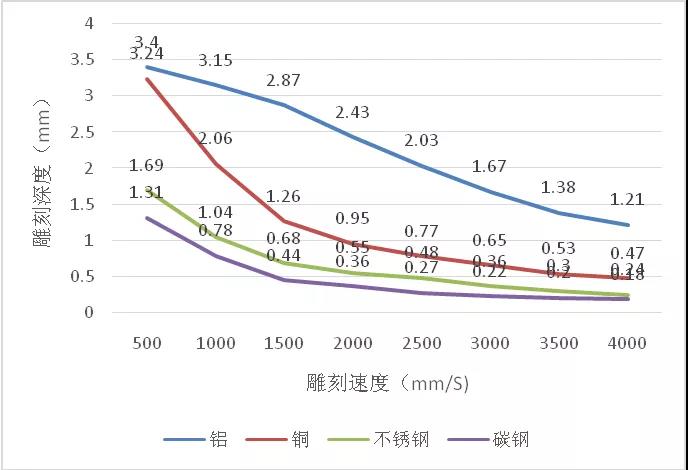

4.Speed affects depth of engraving

At last,as see from the chart, the carving depth decreases with the increase of carving speed.When the carving speed is 500mm/s, the carving depth of each material is the maximum.

So the maximum depths of engraved aluminum, copper, stainless steel and carbon steel are 3.4mm, 3.24mm, 1.69mm and 1.31mm, respectively.

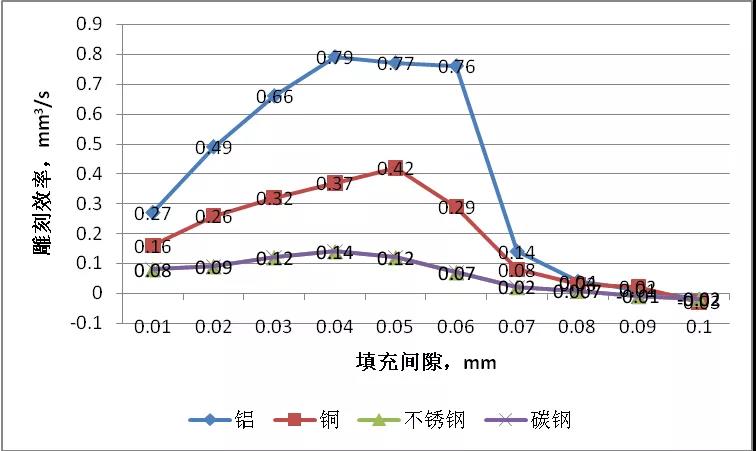

5.Fill spacing affects engraving depth

In the end,the filling density is 0.01mm, the engraving depth of aluminum, maximum brass, stainless steel and carbon steel .The carving depth decreases as the filling gap increases.

However fill spacing increased from 0.01mm to 0.1mm.The time are require to complete 100 carvings was gradually shorten when the filling spacing was greater than 0.04mm.

Finally, the shortening time range obviously reduce.

Conclusion

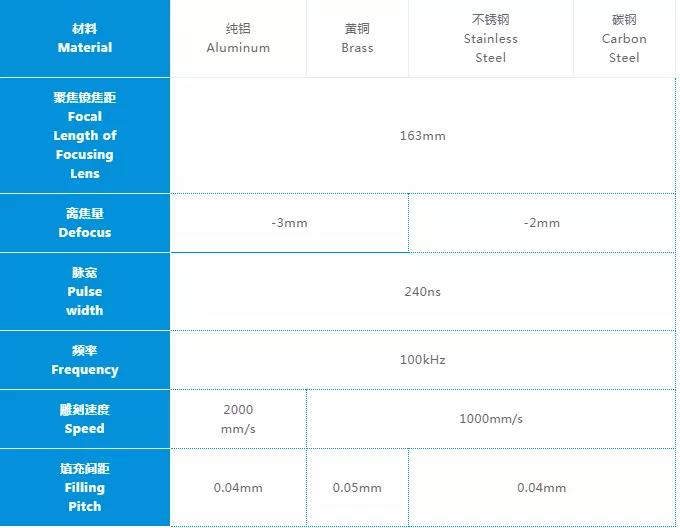

Therefore, through the above tests, we can obtain the recommend process parameters for

deep engraving of different metal materials using rfl-100m:

At last,if you have any confused of machine,welcome to contact XT LASER:

Sales Manager: Kalyn

Mobile/ Skype:+86 189853368889 Email:xintian125@xtlaser.com