Application of Fiber Laser Marking Machine in PCB Board(lisa)

Application of Fiber Laser Marking Machine in PCB Board

Fiber laser marking machine

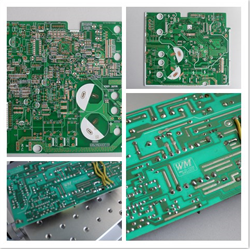

PCB boards, also known as printed circuit boards, are the providers of electrical connections for electronic components.

With the development of the IT industry, smart phones, wearable electronics and other products continue to be thinner and lighter. And consumers are increasingly demanding electronic products. Needs to refine the production of PCBs . To realize the quality control of the PCB production process. The marking of characters, one-dimensional code, two-dimensional code and other information on the PCB board is traced back. which has become the development trend of the industry.

Marking on the surface of the PCB is like pattern drawing, company LOGO printing, contact information, QR code, etc. The people used silk screen printing in traditional printing in the past,. Under the original market demand, traditional printing technology can also meet the requirements of the market. But as the quality of electronic products continues to increase, the requirements of consumers are getting higher and higher. Leading to higher and higher marking quality of PCB boards in the market. Due to poor wear resistance, low precision, poor aesthetics, and environmental pollution, the technology is increasingly unable to adapt to new market technology needs.

Fiber laser marking machine

The emergence of laser marking equipment has successfully solved a series of problems in traditional printing technology. It is with the features of high precision, fast speed and stable performance. Moreover, we control it with computer and the operation is simple, and can print various complicate patterns, characters, two-dimensional codes and the like, which fully meets the requirements of high quality marking of the existing PCB industry.

The fiber laser marking machine developed by Xintian Laser has good marking quality and strong wear resistance. The marking on the surface of the PCB board is clear and also possible to mark beautiful, and various LOGOs, patterns, two-dimensional codes and characters. The laser marking machine adopts non-contact processing, and the laser head does not need to contact the surface of the material, so there is no need to consider damage to the material.