Why choose the high-power laser cutting machine? – Alicia

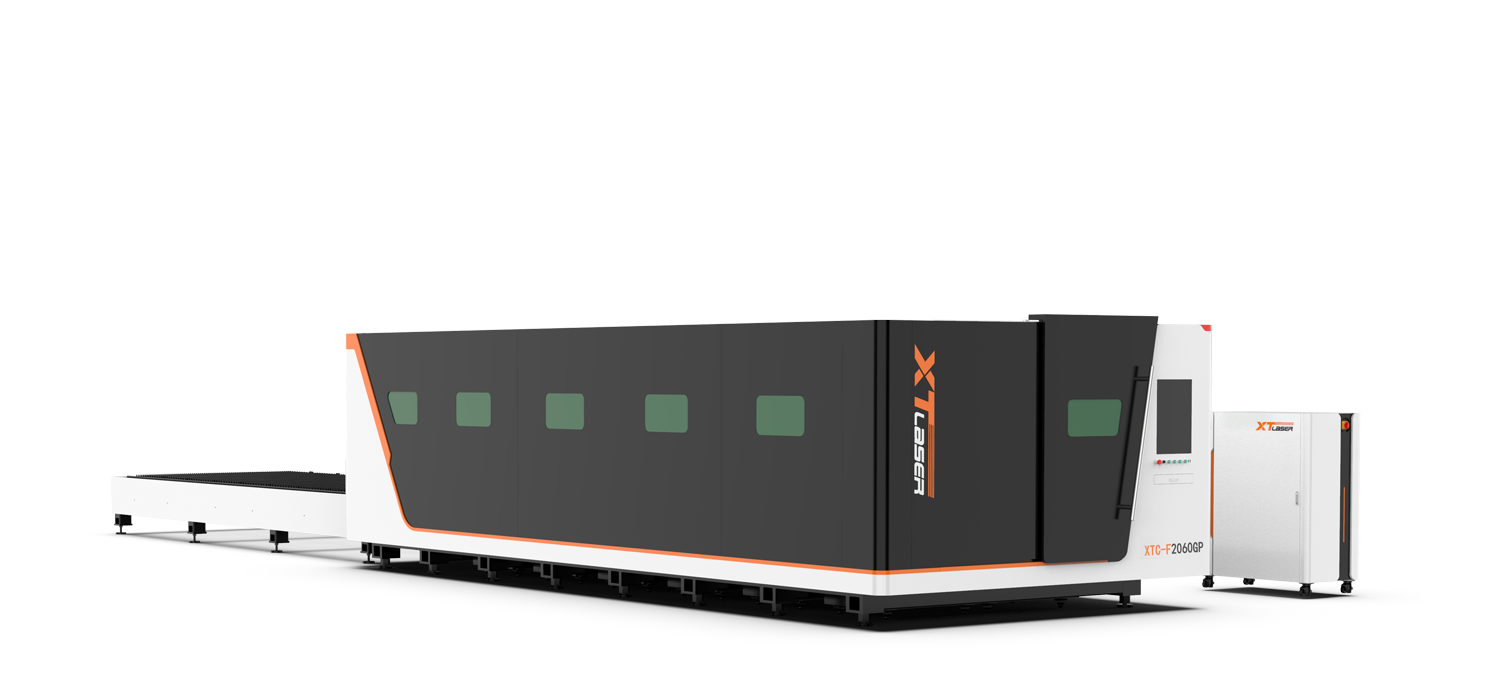

Why choose the high-power laser cutting machine?

New age industrial manufacturing sets new requirements for precision, speed and thickness of sheet metal cutting. The power that the fiber laser cutting machine can reach is increasing more and more, up to 30kw. Whether you are planning to buy a new cutting machine or have a low power one, high-power laser cutting machine can give you a better return on investment.

Some readers may have questions. We only cut 5mm to 10mm plates, why do we need high- power cutting machine? What benefits can it bring us?

1. Save time and money

Taking 5mm stainless steel cutting as an example, the 12kw laser cutting machine runs continuously for 24 hours. Which is equivalent to 6000w laser cutting machine working continuously for 2.7 days, and 3000w laser cutting machine working uninterruptedly for 4.4 days.

For factories, the delivery time can measure the level of processing to a great extent. Because the shorter the delivery time, then the higher your customer satisfaction and the higher your market competitiveness. For self-produced and self-sold customers, faster processing speed means more efficient parts delivery and can easily meet the demand for higher production capacity. And all this will be satisfied by high-power laser cutting machine.

2. The cost of use has not increased significantly.

In addition, the high-power laser cutting machine can use air to cut thin plates, and the cutting effect can be guaranteed. This will further reduce the cost of use and improve the profitability of the business.

3. Better cutting effect

The high power laser cutting machine has a better cross section and a smaller cone. At the same time, it can cut a wider thickness of the glossy surface. It can complete 30mm carbon steel bright surface cutting. The customer of the finished product is more satisfied.

Email: xintian141@xtlaser.com