How to select a proper cutting speed for the fiber laser cut machine(Lisa)

How to select a proper cutting speed for the fiber laser cut machine

How to select a proper cutting speed for the fiber laser cut machine

Effects of different cutting speeds on cutting quality

When the fiber laser cut machine is cutting, the cutting speed is selected in accordance with texture and thickness of plate to be cut. Different cutting speeds will affect the laser cutting quality. A proper cutting speed can improve the efficiency of laser cutting as well as realize good cutting quality, so

Now we discuss the effects of different cutting speeds of fiber laser cut machine to the cutting quality: because

A: Effects of too fast laser cutting speed on the cutting quality:

1) May give rise to cutting failure and have sparks all around. but

2) Some areas can be cut off while others cannot.

3) The whole cutting fracture surface may be end up too rough but without molten stains being produced.

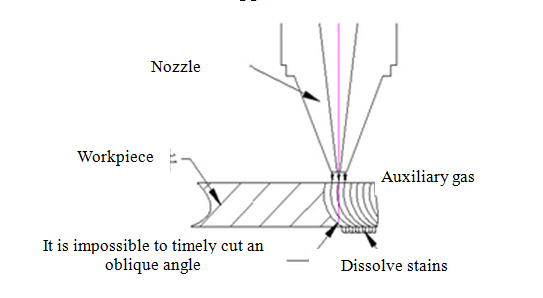

4) The cutting feed speed is too fast, as a result, the plate fail to be timely cut off, slanted bar pattern arises on the cutting surface and molten stains happen to half bottom. As shown in the figure below:

B:Effects of too slow laser cutting speed on the cutting quality:

1) The sheet metal may become over-melted and cutting fracture surface may become rougher.

2) The cut joint may become wider correspondingly, And the small circular bead or sharp corner area may melt down thus we cannot get desire cutting result.

3) Low cutting efficiency influences production capacity. more or less

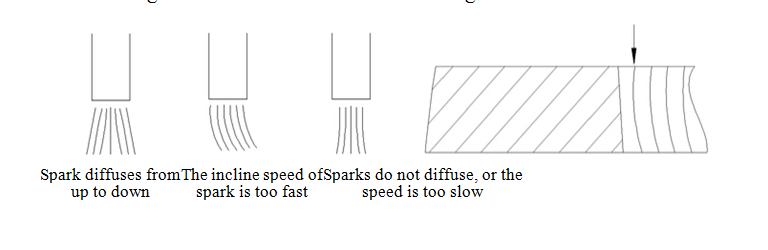

4) Choseing the proper cutting speed: Feed speed can be judged as per cutting sparks: In general, cutting sparks are diffuse from top to bottom. When sparks incline, it means the feed speed is too fast; In case the sparks are not diffused, but gathered together, it indicates that the feeding speed is too low. Appropriate cutting speed arises and smooth line appears on the cutting plane with no molten stains occurring to half bottom. As shown in the figure below:

If any more info, please let us know, my whatsapp and wechat 0086 15954124625.

Contact person: Lisa wang