Notes on laser source installation and disassembly of Fiber laser cutting machine-Max

Notes on installation and disassembly of laser source from Fiber laser cutting machine

First is how to do installation of laser source:

After the laser is placed in the designated detection area, the hardware control connection between the machine and the laser is performed.

Then please ensure that the cutting head and the jumper output lens are clean and the inner lens must be free of dust.

Next is to connect the laser jumper output section to the cutting head and mount it on the machine.

Then Connect the jumper output head and the cutting head waterway and other connecting lines.

The last is to turn on the water circuit and circuit, and turn on the laser without any abnormality.

Second to performace Cutting:

For first step, it is to adjust process parameters (cutting speed, cutting air pressure, focus position, nozzle size, cutting height, perforation parameters, perforation pressure, blowing delay, light emission delay, etc.). And rember to ajust thinner plates for different lasers according to the detection requirements of lasers of different powers Cutting test for thick plates.

Last is on disassembly:

First step is to turn off the laser, circuit, and water path. Secondly, remove the cutting head and jumper output head and clean the remaining water stains on the jumper output head.

Then disassemble the connection between the laser and the machine control line.

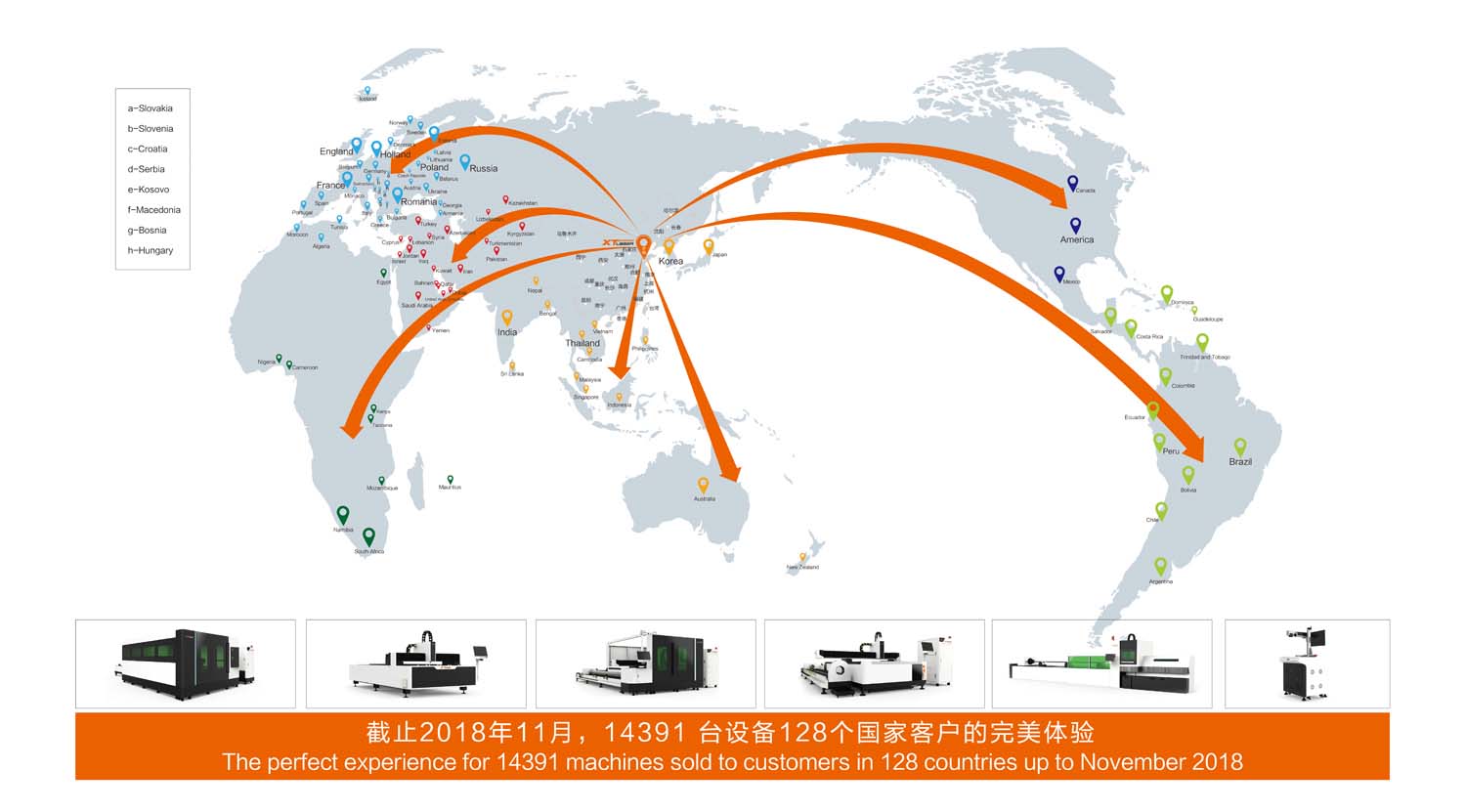

By the way, we are looking for partners and distributors of laser marking, cutting, welding and cleaning in global.

More details will be updated soon. Your bookmark will be the biggest encourage for me.

My email: xintian109@xtlaser.com whatsup: 0086 18353156659