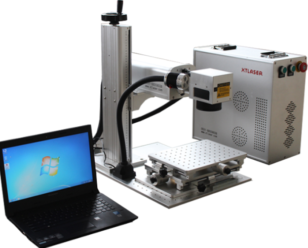

Laser marking machine for engraving engine from Lisa

Laser marking machine for engraving engine

What is Laser Marking of the Engine?

It has become an essential part of the manufacturing and automotive industry as it assists businesses to keep check of their products, minimize simulating, develop quality and more. There are good numbers of benefits for marking in industries for helping understand the perspective behind this technology. The laser technology is one of the most amazing applications to involve with. The major problem found was information regarding engine build for investigation in case any failures occurred. The idea was to install a 2D code onto the engine casing, conversely, this would need multiple marking techniques to mount at the plant.

The Marking Process is Clean and Eco-Friendly:

Chemical Engraving or Inkjet like processes use inks and chemicals in marking that have a negative effect on the surroundings apart from being costly consumables for the industries. The Laser Marking, on the other hand, is way far from using any kind of consumables that makes it reasonable, clean and energy competent. It also excludes downtime and costs related to fixing, cleaning or fueling printers. The products might also get damaged over time due to peel off, tearing or any other reason. But laser marking helps the permanent marking to remain really long, supporting the brand and quality in the industry.

Laser marking promises clean processing at least adulteration since the process cannot contacted. Where printing techniques will lead to burning down of the material by marking, the damage-free process includes no or least material dissemination.

The Marking Procedure:

- Laser marking is the result of when beam comes into contact with the material surface, slightly modifying its features or presentation.

- Obtained by moving a low-mechanical beam gradually across the material using a technique called staining, that produces high-contrast marks without troubling the material.

- Laser raises the material temperature that causes oxidation below the surface and turning the material black.

- The laser marking applies low temperatures to metal to toughen the surface.

- All of this is done while leaving the surface undamaged.

Laser marking is unique from laser etching and laser engraving in a number of ways:

- It is a rare process and not all places provide these services.

- Also known as laser dark marking or laser coloration, and also charring for plastic materials and strengthening for metals.

- There are 4 collective types of laser marking: carbon migration, annealing, coloration, and

- It is very common in the medical device industry for titanium parts and stainless steel but can executed on other materials too.

- A laser marker is perfect for barcodes, QR codes, UID codes, logos and other recognition needs.

Which industries use Laser Marking?

When investing the laser, it was one of the best creations and gained early recognition for its usefulness in different industries. But the laser marking has given modern reach to the flourishing companies by promoting their brand name and assurance for quality.

- Automotive

- Aerospace

- Electronics

- Industrial & Tooling

- Medical

- Military & Defense

- Oil & Gas and more…

For the automotive industry and motorized industries, companies extensively make use of laser marking on the engines. It is the recognition for their appreciation of every automotive manufacturing entity. Every industry uses the laser for different purposes. For instance, the manufacturing companies understand the importance of product branding and therefore. They mostly make use of laser marking on their products and gain recognition in the industry. Not only for the laser marking but also for laser engraving and etching, business widely apply these techniques.

If any information you want to know more about our machine, please contact as below

Mob/whatsapp:008615954124625

Email: lasermachine02@xtlaser.com

Contact person: Lisa Wang