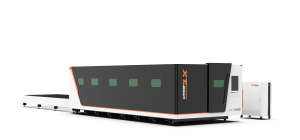

High power fiber laser cutting machine Waterway link connect-Tulsa

High power fiber laser cutting machine Waterway link connect-Tulsa

Waterway link

- The water chiller outputs two waterways, high pressure and low pressure. The high-pressure water path flows to the optical fiber plug and the cutting head. Pay attention to the direction of the water in and out. So that the water flows through the optical fiber plug and then the laser cutting head. The low-pressure water path flows to the fiber optic device. The brand and model of the fiber optic device are different, the water connection method is different. And the specifications and dimensions of each connection pipe are also different. Please recognize the flow direction and label of the water path. And use the water pipe attached to the machine to connect it correctly.

-

Points to note for waterway installation

-Add non-mineral pure water, distilled water or deionized water to the water cooler. It is forbidden to add any corrosive liquid or water with magazines.

-When adding water, avoid any unnecessary contact with water (such as hands). All auxiliary equipment for water injection, such as pumps, hoses, etc.. Should only used in this water cooler.

-Before turning on the power supply of the water chiller, check the water level of the water chiller. It is strictly prohibite to turn on the water chiller when there is no water. Or the water level is too low to avoid damage to the water cooling equipment. It is strictly forbidden to squeeze and step on the water inlet. And outlet pipes of the water cooler to keep the waterway unblocked.

-When the temperature is below 0℃, the cooling water in the water cooler. Laser and water pipes should discharged when the temperature is below 0℃ for a long time. To avoid freezing of the cooling water and damage to the equipment and pipelines.

-It is recommend to completely replace the water in the water chiller every two to three months.