Take one minute to know fiber laser welding machine-Teresa

Take one minute to know fiber laser welding machine

In industrial manufacturing, laser equipments are popular in marking, cutting, welding and other fields. Fiber laser welding machine has become a major trend at present. This is because of the many advantages of fiber laser welding machine.

1. Advantages of fiber laser welding machine:

Firstly, good processing stability

The heat input can be reduced to the minimum required amount. The metallographic change range of the heat-affected zone is small. And the deformation caused by heat conduction is also the lowest.

Secondly, high processing efficiency

It can reduce the time required for welding thick plates and even save the use of filler metal.

Thirdly, less machine loss

There is no need to use electrodes, and there is no concern about electrode contamination or damage; non-contact welding process. This can make the wear and deformation of the equipment be minimized.

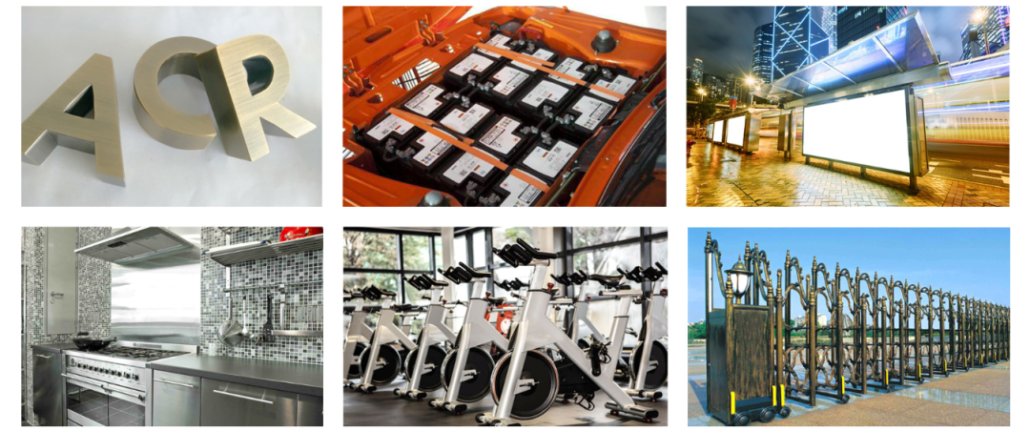

Fourthly, wide processing range

The workpiece can be placed in a closed space (under vacuum or internal gas environment under control). The laser beam will focus on a small area. It can weld small and closely spaced parts, can weld a wide range of materials, and can also join various heterogeneous materials. It is easy to automate high-speed welding and can also be controlled by digital or computer. When welding thin materials or thin-diameter wires, it is not as easy to have trouble like arc welding.

Fifthly, small processing conditions

It is can accurately align the weldment and not affected by the magnetic field. (arc welding and electron beam welding are easy to be affected by the magnetic field). It can weld two metals with different physical properties (such as different resistances). Don’t need vacuum or X-ray protection.

2. XTLASER handheld fiber laser welding machine:

Firstly, simple and easy to operate

Simple and easy operation, no deformation of the welding seam; stable laser output to ensure welding consistency; high power density after laser focusing; fast speed, large depth and small deformation; 360-degree micro-welding without dead angles.

Secondly, fast welding speed

It is more than twice that of solid YAG laser welding, and 3-5 times that of argon arc welding; it saves cost, is stable and worry-free.

Thirdly, beautiful welding process

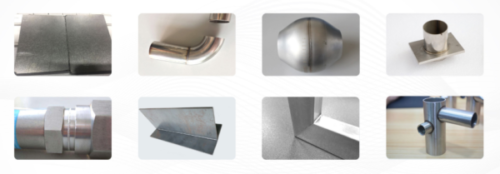

Breaking through the limitations of the original workbench, it is suitable for all kinds of complex welding seams, and it is easy to weld any part of the workpiece at any angle. The humanized design and technology upgrade can produce beautiful welding seams.

Fourthly, swing welding head

The process that traditional magnetic head cannot complete, the swing welding head only needs to use 70% of the power, which can save the cost of the laser;

The swing welding method, the width of the welding point is adjustable, and the welding fault tolerance is strong, which makes up for the small shortcomings of the laser welding point, expands the tolerance range of the processed parts and the width of the welding seam. Thus obtains a better welding seam forming effect.

Fifthly, 360 degree micro welding

After the laser beam is focused, a small spot can be obtained, which can be accurately positioned and used for group welding of small and micro-sized workpieces to realize mass production. Mainly used for welding thin-walled materials and precision parts. It can realize spot welding, butt welding, stitch welding, sealing welding, etc. It has high aspect ratio, small weld width, small affected area, small deformation, fast welding speed. What’s more, do not need to process or simple handling after welding.

For more information, welcome to contact us.

Email: xintian105@xtlaser.com

Whatsapp: +8615006829603

Skype: xtlaser Teresa