Cause of occurring of burr deeply analyse – Damon

Analyze the cause of occurring of burr deeply. Laser cutting machine has become the standard for metal sheet processing due to its high processing efficiency and high cutting quality . However, when some customers use laser cutting, there are any burrs on the front and back surfaces of the sub-material. But it need to inject more manpower to polish the burrs. So it is time-consuming and laborious. It is not due to the laser cutter itself but improper operation.

In the process of plate processing, the purity of the auxiliary gas of the fiber laser cutter and the cutting data parameters will affect the processing quality. So what is a burr?

The burr is the residue particles that melted on the surface of the metal material — the energy from the laser beam focuse on the surface of the workpiece to vaporize the surface of the workpiece and blow out the slag. Due to improper follow-up operations, the melt didn’t not clean in time and “wall-mount” on the surface of the sub-material. Let’s analyze the cause of occurring of burr deeply.

1. Auxiliary gas-air pressure, purity

When the material in the cut line melte, the auxiliary gas will blow out the slag in the cutting groove on the surface of the workpiece. If no gas, slag will generate after cooling. Therefore, the air pressure of the gas should be sufficient( too small to blow clean-adhesion, cut-off; too large to melt-large cross-section lines, diagonal lines). And the air pressure varies depending on the plate, you can find the appropriate air pressure through the proof test. And the auxiliary gas must be pure. Impurity causes the laser head to run at a reduced speed on the surface of the workpiece. The auxiliary gas cannot produce a sufficient chemical reaction with the sub-materials. The rate becomes slow, the cut is rough or it cannot cut through.

● Cause of occurring of burr – When oxygen (auxiliary gas) is used to cut the carbon steel sheet:

When the thickness of the thin plate is increased from 1mm to 5mm, the cutting pressure range is sequentially reduced to 0.1-0.3MPa, 0.1-0.2MPa, 0.08-0.16MPa, 0.08-0.12MPa, 0.06-0.12MPa; When the thickness of medium-thick carbon steel sheet is increased from 6mm to 10mm, the corresponding auxiliary gas-oxygen pressure ranges are sequentially reduced to 0.06-0.12MPa, 0.05-0.10MPa, 0.05-0.10MPa;

● When nitrogen (auxiliary gas) cuts stainless steel plate:

When its thickness increase from 1mm to 6mm, the cutting pressure transitions from 0.8-2.0MPa to 1.0-2.0MPa to 1.2-2.0MPa. It is a high-pressure cutting.

. Parameter setting-focus position, cutting lead-in position

After the customer has prepared the laser cutter, it is best to let the experienced operator debug the equipment. Therefore, it is necessary to adjust the cutting parameters to the best. Air pressure, flow rate, focal length, and cutting speed must adjust several times.

If the focus position is too high, the burr will “swell”, and the burr is very hard and the sides are not smooth. It is also necessary to adjust the focus position multiple times.

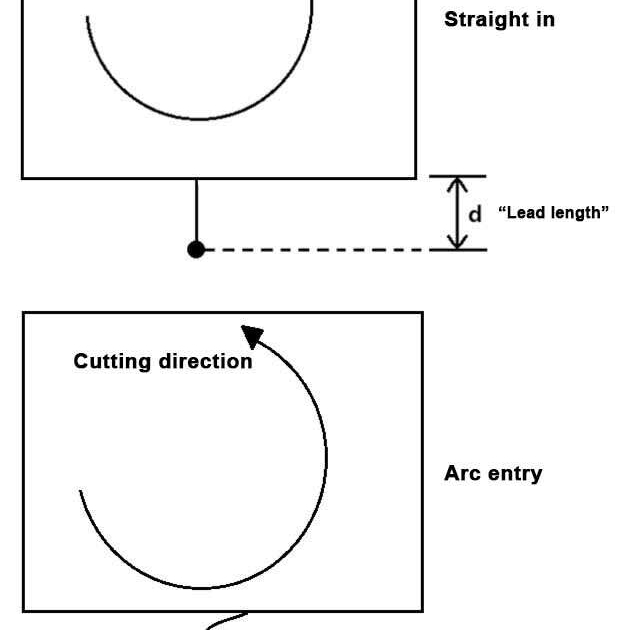

The lead-in line should be far away from the sub-material to prevent local overheating, and “melt knobs” appear on the back of the sub-material. The lead-in is relative to the pilot arc hole. The arc-starting hole is also called “cutting starting hole”. The diameter of the arc-starting hole is larger than the normal slit. Therefore, to improve the cutting quality and save sheet material, the arc-starting hole should be placed at a scrap of the sheet material. Besides, there are two ways to introduce lines: straight lines and circular arcs.