حماية ماكينات القطع بليزر الألياف في الشتاء سيرينا

Protection of the Fiber Laser Cutting Machines in Winter

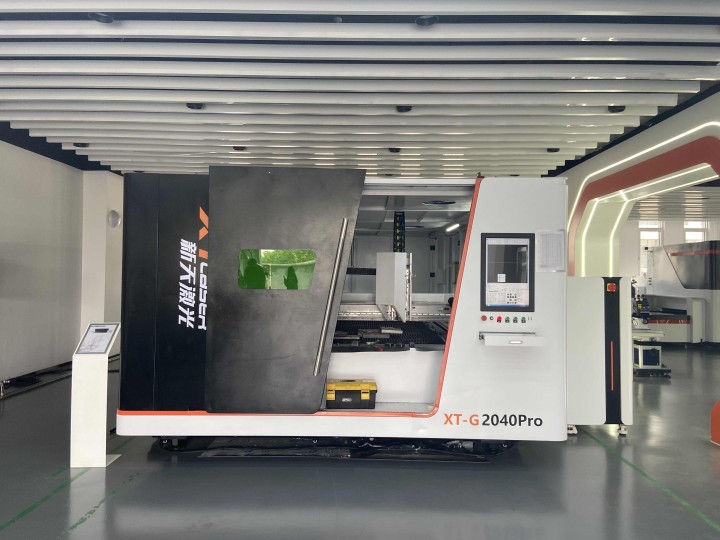

ماكينات القطع بليزر الألياف are used in various applications throughout the year. And regular maintenance is essential to keep them in top condition. In winter, this is particularly prominent. In order to avoid downtime and unnecessary losses. Be sure to take appropriate anti-freezing measures. These are some tips for maintaining fiber laser cutting machines protection in winter.

تيemperature

(1) The working environment of the fiber laser cutting machine in winter is harsh. It is necessary to maintain the temperature of the working environment above zero and provide heating when necessary. If there will be no power outage in the local area. The water chiller will not be turned off at night. At the same time, to save energy, adjust the temperature of low and normal temperature water to 5~10℃. It can ensure that the cooling water is in a circulating state and the temperature is not lower than the freezing point.

Although the temperature does not have a great influence on the fiber laser cutting machine. Because many users will add butter to the screw rod. They will definitely forget to clean it in winter. It causes the movement of the fiber laser cutting machine every time it is turned on. For example, the winter in the north is very cold. The temperature of the studio will be very low, although the machine still can’t move after oil is added. At this time, we must ensure that the temperature in the working room reaches the low temperature of the refueling standard.

Cooling دبليوater for laser cutting machines protection

(1) If the equipment is working continuously, the water flow of the chiller is in a flowing state for a long time, and it usually does not freeze.

(2) The temperature in summer is high, and the temperature of the cooling water must be within the range specified by the equipment. Otherwise, the fiber laser cutting machine will trigger an alarm if the temperature exceeds a certain temperature, which will have a certain impact on the equipment.

Drainage مethod

Water tank drain: Open the drain valve (or drain plug) at the bottom of the water tank to drain the water in the water tank. If necessary, you can tilt the water cooler to a certain angle to make the drainage clean.

Drainage of pipes and lasers: first unplug the plug of the four-way water pipe, and then use compressed air to blow from the drain and outlet of the pipe for one minute to force the water stored in the pipe to flow back to the water tank and the drain. Water from the water tank drain .

Unscrew the filter element in the chiller and drain the water from the filter element.