Any questions clients will be concerned about fiber laser cutting machine-Tulsa

Any questions clients will be concerned about fiber laser cutting machine-Tulsa

Questions clients will be concerned: How are you doing machine installation during Covid

(1). Before shipment, we will do cutting text for client, send picture and video to them, so that they can make sure machine is working well.

Leave the cutting parameter of material and thickness you need to cut in laptop, so that you no need to adjust parameter in cutting process.

(2). In order to shipment, we need to remove any parts then client installation it when machine arrived.

I will take picture and video of which line connect with which parts, how to connect. Send video and picture to you.

Sheet metal, we will mark number on package, you will know which parts installtion where it is.

(3). Operation

After shipment, we will send demo machine working software to you, you can installation on your laptop.

So that you can try to learn and use it on your laptop.

Cypcut software is easy to use, even if a girl not very interested in machine working like me, can operation it very well, so no worrys.

(4).Use manu

We will send Use manu to you, English version

(5). We have online English after-sale service team, they will deal with your problem 24 hours, 7 days every week.

They will have a video chat to tell you how to installation and adjustment, if any problems, they will deal with you also.

Questions clients will be concerned: What is the best way to avoid the head hitting scrap pieces that pop up?

In the cutting process, will not produce debris in normal situation, are you mean spark?

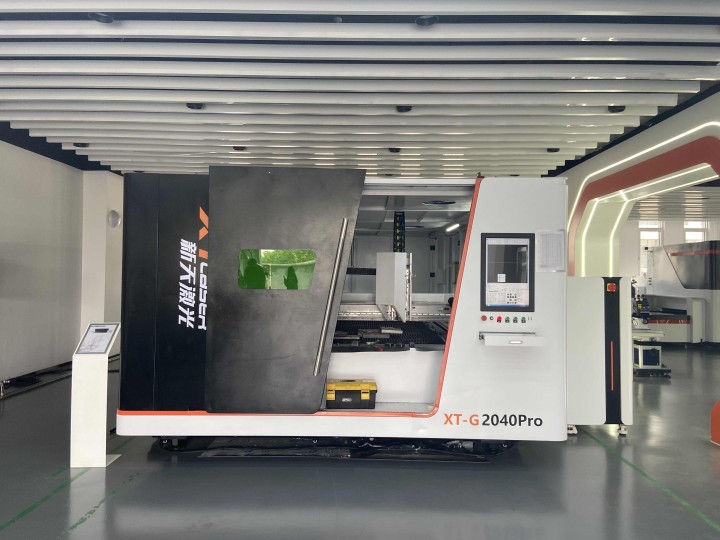

If you choose G type, when you cutting, the door must be closed, so no worrys.

If choose H, because it’s open type, we use this protector to avoid spark splash.

And, in the cutting process, will have smoke, Fan smoker isstandard in machine spec.

Especially G type, we have 2 sets Fan smoker systerm, one is above the cutting platform and the other is below the cutting platform. Partition dust removal is also standard.

When you cut this part,this part will be dusted, which is cleaner and more precise.

Questions clients will be concerned: one of our panels have more than one thousand cut openings. It would be very time

consuming to manually select the cut path.

No need to manually select the cut path.

The software we use is Cypcut 2000, it include nesting function.

Just seeting cutting speed, air preasure, height, then cut, software will find cut path automatic.

More than 1000w, cutting head is auto-focus adjustment cutting head, will adjust focus automatic.

Questions clients will be concerned: It looks like the machine does not have collision avoidance?

It’s standard also, no worrys.

During the cutting process, if the obstacle is within the Z-axis travel range (H type: 100mm, G type: 350mm) of the cutting head, the cutting head will automatically avoid the obstacle.

There is a capacitance controller in the cutting head, which can automatically detect obstacles.

If the cutting head collides with an obstacle, the most common situation is that the capacitor controller fails and is not powered, so the obstacle cannot be detected.

But this situation is very, very rare, almost negligible in our after-sale feedback and experience.